Injection moulds are required for the production of almost all products in daily use and, therefore, they represent a huge market worldwide. The variety of requirements for the shaping mould directly correlates with the requirements for the plastic component.

Our product and service range for injection moulds can be characterised as follows:

Dimensions:

- Mould dimensions up to approx. 1200 x 800 mm

- Injection weights from 0.6 g to approx. 750 g

Construction types:

- Pilot and prototype moulds

- Multi-cavity moulds

- Hybrid moulds

- Stack moulds

- Tandem moulds

Further special designs:

- Film insert moulding / in-mould labelling

- Over-moulding of metal parts

- Variotherm® technology as well as air extraction of cavities to optimise the surface quality

- Conformal cooling using diffusion welding and selective laser sintering (SLS)

- Spindle tools for threads of packaging and technical parts (driven by cylinder and rack or by electric motor with chain drive or by a completely electric spindle unit)

- Highly transparent clear parts and displays made from PMMA

- High-temperature applications (PFA, Peek, PA-GF)

- Fibre-glass reinforced plastics

- Injection moulds for thermosets

Typical applications:

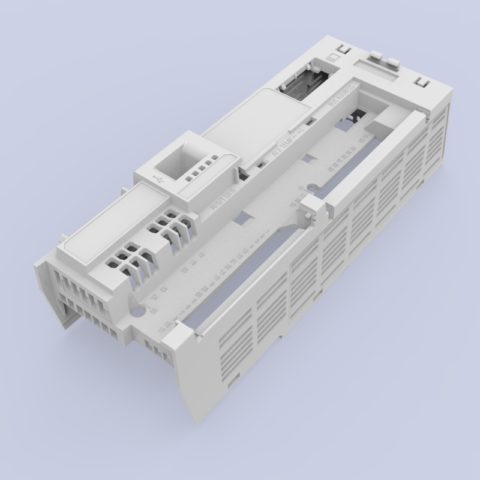

- Automobile industry

Visible and functional parts in the interior, head-up displays, engine periphery - Packaging

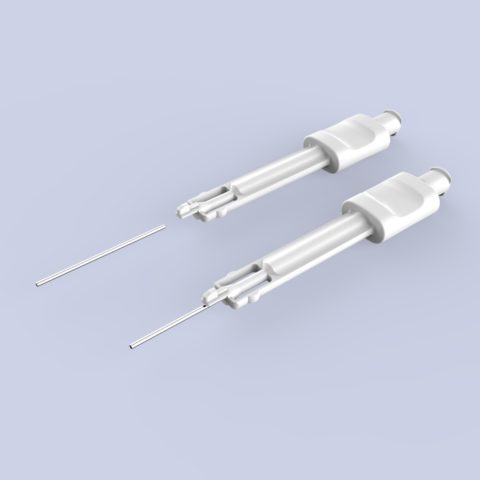

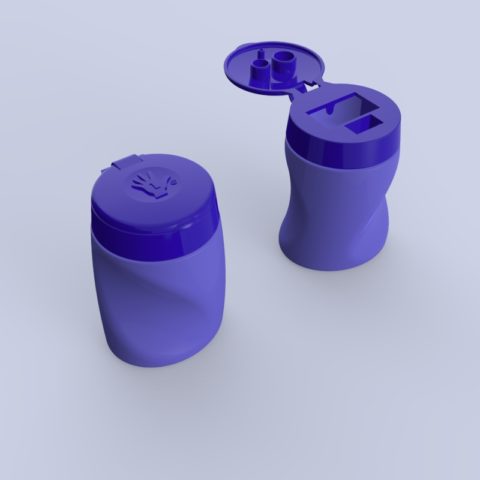

Snap and screw closures, covers, containers and jars with thick walls - Pharmacy

Components for medical devices and supplies - Plumbing

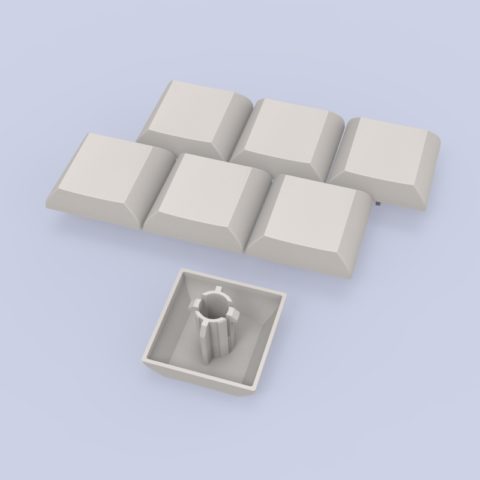

Hose fittings, pipes, connectors - Communications

Keypads

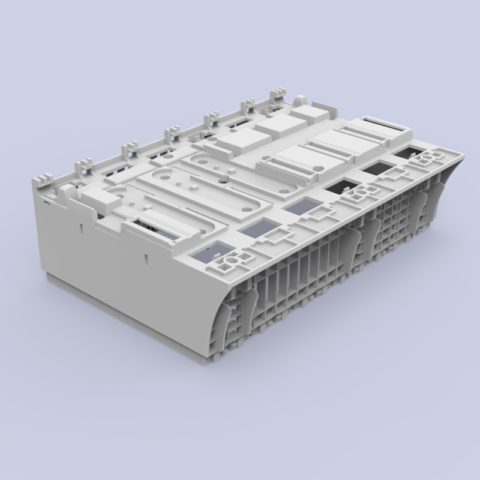

Examples of applications for injection moulding

You can find some of our references for injection moulds here.

REBHAN Werkzeugbau GmbH

Industriestraße 13

96317 Kronach, Germany

Phone: +49 9261 6025-0

E-Mail: info@rebhan-wzb.de

© Rebhan Werkzeugbau 2018 · Design: Hering‘s Büro