Following the construction and production planning, the tool components are manufactured using our modern and well-equipped machinery.

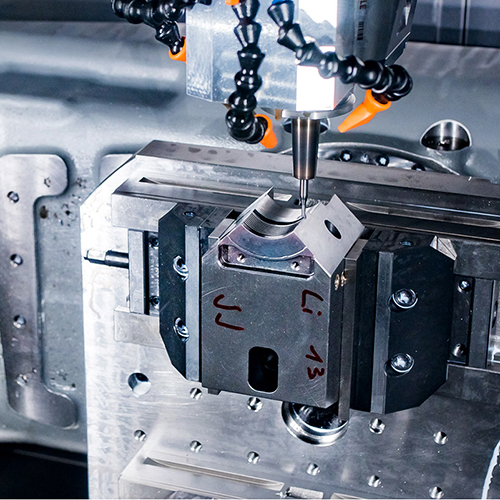

In partially air-conditioned production areas, all the significant technologies are at hand. CNC milling, HSC milling, CNC turning, wire and die-sinking EDM, flat, round and coordinate grinding stand for quality and precision. Our key machines are automated and can thus run unmanned round the clock – cost effective for shorted project lead times.

For NC programming we use the most actual CAM software hyperMill® from OPEN MIND Technologies.

Our technical equipment allows us to create mould sizes up to 1,200 x 800 mm and / or with a weight of up to approx. 4 tonnes.

Good to know: Our capacity is also available for all kinds of contract manufacturing.

Some examples from our machinery:

An important all-rounder:

Our Hermle 5-axis machining centre C32 is equipped with a 7-fold pallet changer and an additional magazine with 88 tool stations.

Efficient small-batch manufacturing:

With the Indumatik Ultralight, up to 16 workpieces can be automatically fed to 5-sided milling processing.

Flexibility in eroding:

Each OPS Gantry Eagle 500 and 800 are operated by an Erowa Robot System with electrodes and workpieces in a production cell.

Perfectly round:

A Studer S31 is available for challenging cylindrical grinding work with high-accuracy requirements.

Useful rounding off:

With the Trumpf TruMark 5010 marking laser, components can be cleanly labelled, and the most delicate script can be added in the cavity

Without people, nothing would work:

Our employees’ expertise makes this advanced technology at all manageable. Not least because, despite all the technology, some craftsmanship is still required for tool making.

REBHAN Werkzeugbau GmbH

Industriestraße 13

96317 Kronach, Germany

Phone: +49 9261 6025-0

E-Mail: info@rebhan-wzb.de

© Rebhan Werkzeugbau 2018 · Design: Hering‘s Büro